I’ve watched a metric ton of van build/tour videos in recent months, squirreling away ideas and concepts that I intend to shamelessly poach for my own eventual project. I think I’ve got a fairly solid plan for addressing several features into one compact area.

Pico projector and projection screen

One of those is something several folks have done, which is to install a pico projector and a roll-up screen, for TV or computer use while out on the road.

One setup I thought was amazingly clever was this one by a fellow named Luke; he mounted his pico projector to a small platform and built it into his ceiling. All the wiring is hidden (but also generally unreachable) and the platform sits flush with the rest of the ceiling when stowed away – brilliant! The obvious issue with this would be that the ceiling would have to be lower than it likely would otherwise, unless one simply foregos insulation in that area, to make room for the projector. Considering we’re talking the ceiling, and heat rises, this pocket would likely be a route for heat to escape; but it’s such a small area, I expect the loss would be so minimal as to not be worth worrying about.

The other component would be the projector screen. Luke does something clever with this as well; but his cabin is very wide open, and my plan doesn’t allow for that, so I’m looking at something different.

Electrical system – monitors, fuses/breakers

The common solution to van electrical system installs is to build one’s bed platform up a couple or three feet from the floor, and to use the space beneath as a “garage”, for gear storage but also as an out-of-the-way spot to install water tanks and electrical systems (these two being on either side against the walls).

A well-designed, robust electrical system will have several components solely added for safety. Fuses, breakers, cut-off switches – and I have every intention to go this route as well. Lots of very tried-and-true designs out there to use as guides. But, my problem with these setups is accessability; more often than not, and in nearly every van build I’ve personally put eyeballs on (all of three, so far), the electrical system and these switches are mostly inaccessable in a pinch, due to storage bins or other random gear being stuffed into the garage right in front! If something goes horribly wrong, or even in the most minor way – a 12v fuse burns out and needs replacing at some point – it’s a huge PITA to get access.

So, my working plan is to move much of that safety gear to somewhere else in the van, somewhere hidden but also very easily accessable. The big downside of this plan is wiring. The thickness (gauge) wiring you use between Component A and Component B is 100% dependent on the amount of juice that will be flowing through that wire; the more juice, the thicker the wire is required. It’s stupid easy to melt wires by overloading them. Beyond that, longer wire runs means the current being pushed from the source needs to be higher in order to reach the device being powered at the level necessary; there’s attenuation involved.

Now, some of the wiring I plan to terminate in this more accessable space will end up shorter than it would be if I did the traditional electric system install, but some will be longer; and much of the longer runs will be the thicker cabling, and that thicker gauge wire can get expensive. I haven’t yet sat down and puzzled out what components I would relocate, and what gauge wiring would need to be extended by several multiples; I think I’ll tackle that very soon and try and settle on a workable, not-bank-breaking solution.

Pantry

Most everyone has a kitchen setup of some sort, and those always involve food storage. Many simply do sliding drawers, or overhead cabinets; some just do plastic storage bins slid into a cubby.

Cubic footage in a van is very limited, and the more usage you can get out of this limited resource, the better. You can fit a lot into a drawer; items can be stacked on top of other items. The same with bins. Overhead cabinets, that’s trickier as the door opens outward as opposed to drawers/bins which have walls.

Cubic footage in a van is very limited, and the more usage you can get out of this limited resource, the better. You can fit a lot into a drawer; items can be stacked on top of other items. The same with bins. Overhead cabinets, that’s trickier as the door opens outward as opposed to drawers/bins which have walls.

Something I’ve seen a couple of van builds employ is the skinny sliding pantry setup that you can find in residential kitchens. There’s one company called Rev-A-Shelf that offer several different models of these sliding pantries; widths of three, five, eight inches, and varying heights. I’m looking at the five-inch model, largely so I can tuck cans of soups or vegetables in there; the three-inch shelf spaces won’t accomodate those cans, and are basically only good for spice jars. I intend to go with the magnetic-lid spice jar plan anyway.

The Final Solution!

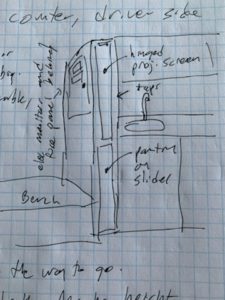

Behold, my horrible sketching skills and terrible handwriting!

Behold, my horrible sketching skills and terrible handwriting!

This whole setup will be on the driver’s side, about midpoint in the cabin front-to-back, and extend fully from the ceiling to the floor. Forward of this feature will be the kitchen setup – counter and drawers below, overhead cabinets above, running all the way to the bulkhead behind the driver’s door. Behind will be a bench, and the bed platform/garage behind that. (The bed design, which I’ve gone over in other posts, will extend over the bench and stop just before, or perhaps snug with, this vertical feature.)

I figure I’ll make this structure around six inches thick; partially to accomodate the sliding pantry at the bottom, and partly to allow plenty of room at the top for electrical component installs. (Edit: I may need to rethink this area a bit. The pantry setup linked above needs a 5.5″ opening; and if I use 1″ 80/20 rails for structure, that’s another two inches, 7.5″ total. I expect I have plenty of space forward for cabinets/etc that I can lose this extra space. But, I may just look at fabricating my own pantry shelf solution; something less wide than 5″, but still wide enough to hold the containers I intend to store there.)

I plan on using the Rev-A-Shelf pantry product I linked above; but I’m debating which model to go with. There’s two I’ve got my eye on; and in the tradition of Goldilocks and the Three Bears, one is too short; one is too long; none of them is juuuuust right. I’m leaning toward getting the too-long model, taking it apart and shortening it. The trick there will be the sliding mechanism; it appears to be a structure of three drawer slides. That should be easy enough to just swap out with shorter slides, if need be.

The rearward facing section at the top will have a hinged door, with various monitors and controls visible; inside that space will be the 12v fuse panel at least, and if the plan works out, any 110v breakers and system cutoffs. All of this gear will sit a few inches back from the outer face, which will have a long slender surface mounted with a hinge, and a projector screen mounted on the inner side. Unlatch this piece, rotate it up ninety degrees, fix it in place (however I figure out how to do that), pull the now-horizontal screen down, and boom, a viewing surface!

And also, on the kitchen side of this whole setup, there’ll be another small feature which I will cover in another post…

This is all very pie-in-the-sky at the moment; I’m hoping I can make all this work.